One of the most challenging parts of 3D printing is deciding what can be printed. During the sales process, it is common for a contract manufacturer to refuse to bid, or ‘no-bid’, parts that they believe too difficult to print. Why? Even though advancements in 3D printing are significantly increasing the number of legacy parts that can be made, contract manufacturers might not be aware of these advances and simply put your bid in the bin.

Education Doesn’t Drive Growth

Some companies believe the issue is with the selling process itself. They believe the industry just “needs more education” on which parts to avoid for printing. They train their sales professionals to avoid problem parts. When they see a particular geometry, they steer the conversation away from the part entirely. Customers eventually learn the technical limits and stop asking for a bid or cease creating these types of parts altogether. Unfortunately, this approach doesn’t increase revenue or improve customer satisfaction.

SupportFree Printing Expands The Market

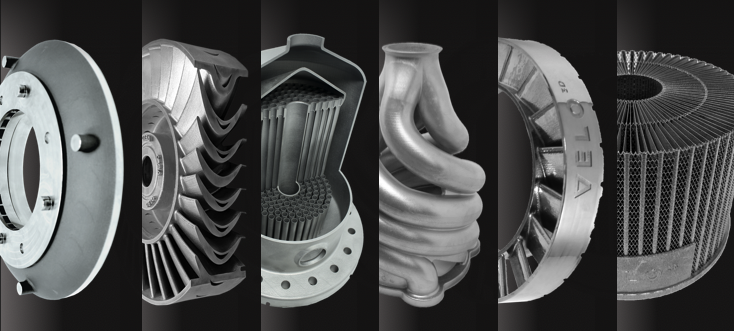

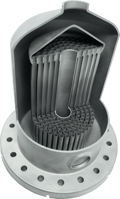

Instead, as a metal AM printer manufacturer, we should be focused on enabling the industry to print those parts in the first place! Printer technology historically has been the limiting factor to printing complex geometries. But VELO3D SupportFree printing capabilities expands what is possible to print and converts the no-bids into a new and growing source of revenue. What used to be considered no-bid parts can now become lucrative business opportunities. Here are some examples of part features that normally would have been considered no-bid triggers:

|

|

Tall parts |

|

|

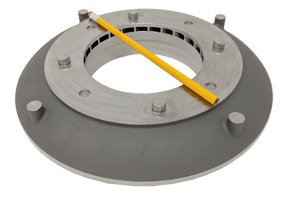

Large inner diameter Parts |

|

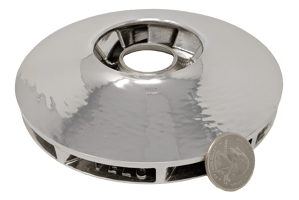

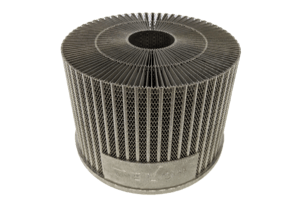

Low Angle Impellers |

|

High Aspect Ratios |

|

Large Titanium Parts |

Expand your designs, and your revenue

Besides just being able to write more proposals and take more orders, there is also the opportunity to expand the business options beyond the current status quo. The largest challenge with being able to finally print no-bid parts is one of our own making. By adopting the strategy of re-educating to ‘design for additive’, many of the designs that need advanced geometries that have the potential to create large additional value for end products are no longer being created. The industry has educated designers to a lower standard than what is now possible. Well, now it’s time to re-educate the industry on a new narrative: additive for design instead of design for additive.

The Win-Win Sales Model

VELO3D is tackling that challenge by working directly with OEM partners on their part needs and finding opportunities to free them from the limitations of legacy metal 3d printing. By working directly with these innovative companies, VELO3D is helping designers understand what is possible when the constraints are removed. Our process is simple. We start by examining a company’s portfolio of parts and then filter down to the find the parts with the largest business impact. Many times, these are parts that the OEM has attempted and failed to print on other printers.

After finding the right part, we select a single part to prove the capabilities of the VELO3D system. For many of our customers, their journey to 3d printing is quicker than they anticipated. By starting with one single part, they begin to understand the new possibilities and can qualify 3d printing as a production technology. This opens them up to more design choices and creates more opportunities for innovation. We then connect our OEM partners to our manufacturing alliance of contract manufacturers, including companies like Stratasys Direct, Knust-Godwin, and Proto Labs who print the parts in production quantity. Whether you need on-demand manufacturing of existing designs or improved geometric freedom for your next innovation - if your part is made from Titanium, Inconel, or Aluminum and you can shoot it through a basketball hoop - our CMs can print it.

VELO3D is helping drive a fundamental change in the AM market. By making more designs possible, we free designers from the limitations of old technology, and accelerate the move to serial manufacturing of additive parts. I’d love to hear from you about your no-bid challenges, or your impossible parts – or just if you want to talk more about making metal AM work well for your applications. Our build plate is 315mm in diameter and enables builds of 400mm in z-height. If you have parts that meet these dimensions and you currently manufacture in Inconel, Titanium, or aluminum, give me a ping and let’s geek out on some part making challenges.