Engineers have long understood that keeping components at their critical operating temperature leads to higher performance and longer lifetimes. Adding cooling channels into a design to aid in thermal management can be both difficult to design and expensive to manufacture. Through the use of nTopology and VELO3D’s advanced solution managing heat in your systems is easier than ever.

Watch this webinar and hear how:

Watch this webinar and hear how:

- nTopology’s design software accelerates and simplifies the challenge of reaching the optimal design

- VELO3D’s advanced metal additive manufacturing solution eliminates the compromises imposed by traditional manufacturing

- These next-generation tools combine to produce a lightweight part with conformal channels that improves system efficiency and extends part life.

Application Benefit:

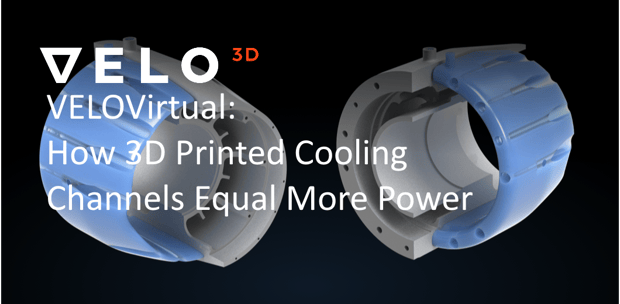

KW Micro Power have been working toward a 30kW generator for terrestrial and aviation power generation markets. A critical component of this design is the generator housing. Originally designed as a bulk part to be machined from a billet, KW Micro Power wanted to examine the possibility of light weighting the design and making the design multi-functional.

By leveraging nTopology's next generation software, they were able to create a design that reduced the weight by 44%, added active cooling for the housing, and enabled pre-heat of the fuel to achieve higher combustion efficiency. Furthermore, because the part is printed as a single unit, they could eliminate the need for tight tolerances on a mulit-part assembly.

- Light weighting by 44%

- Active cooling using fuel

- Preheating of fuel

- Eliminate tolerances

"Design and manufacturing are inseparable - to innovate, both have to move forward. The combination of these two technologies give me freedom of design - it enables us to overcome challenges and achieve our goals: light weighting, cooling, improving efficiency from heating the fuel" - Enrique Enriquez, President, KW MicroPower

Speakers:

Enrique Enriquez, President, KW Micro Power

Mr. Enriquez is a former Rolls Royce Aerospace engineer and for the past 20 years has been developing microturbines for shaft power and turbojets. His teams have developed several microturbines for the U.S Army, DARPA, SPAWAR, Northrop Grumman and BOEING. He presently leads KW Micro Power in developing a line of advanced microturbines for power generation. KW Micro Power designs and manufactures compact turbogenerators for high power density energy generation. They optimized their aerospace-grade APU using nTopology and VELO3D’s unique capabilities.

Mr. Enriquez is a former Rolls Royce Aerospace engineer and for the past 20 years has been developing microturbines for shaft power and turbojets. His teams have developed several microturbines for the U.S Army, DARPA, SPAWAR, Northrop Grumman and BOEING. He presently leads KW Micro Power in developing a line of advanced microturbines for power generation. KW Micro Power designs and manufactures compact turbogenerators for high power density energy generation. They optimized their aerospace-grade APU using nTopology and VELO3D’s unique capabilities.

Dr. Ryan P. O'Hara, Technical Director for Aerospace and Defense, nTopology

Dr. O'Hara joined nTopology in April 2019 after 20 years of military service in the United States Air Force as a Developmental Engineer. His technical focus is on the application of Mechanical Structures and Structural Dynamics to Aerospace Systems. Areas of interest include turbine engines, laminate composites, meta-materials, and additive manufacturing. Prior to starting at nTopology, he was in academia as an Assistant Professor in the Department of Aeronautics and Astronautics at the US Air Force Institute of Technology.

Dr. O'Hara joined nTopology in April 2019 after 20 years of military service in the United States Air Force as a Developmental Engineer. His technical focus is on the application of Mechanical Structures and Structural Dynamics to Aerospace Systems. Areas of interest include turbine engines, laminate composites, meta-materials, and additive manufacturing. Prior to starting at nTopology, he was in academia as an Assistant Professor in the Department of Aeronautics and Astronautics at the US Air Force Institute of Technology.

Gene Miller, Senior Applications Engineer, VELO3D

Mr. Miller joined VELO3D in 2016 as a process engineer working on developing SupportFree metal AM processes. Prior to joining VELO3D, he held various positions in foundry and process engineering. Gene holds a BS in Mechanical Engineering from Colorado State University.

Mr. Miller joined VELO3D in 2016 as a process engineer working on developing SupportFree metal AM processes. Prior to joining VELO3D, he held various positions in foundry and process engineering. Gene holds a BS in Mechanical Engineering from Colorado State University.